-

SCRF Selective Catalytic Reduction Filter

1.What is SCRF

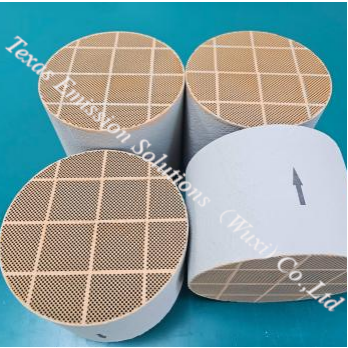

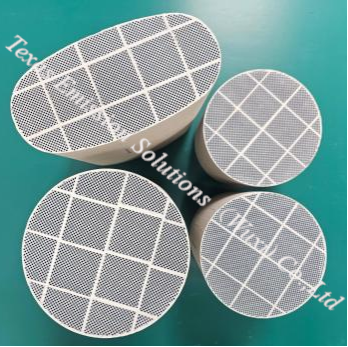

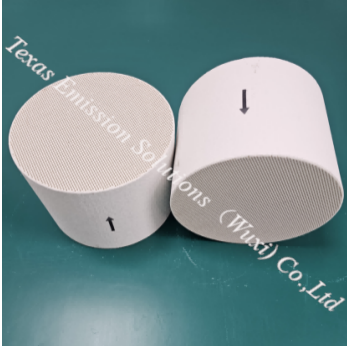

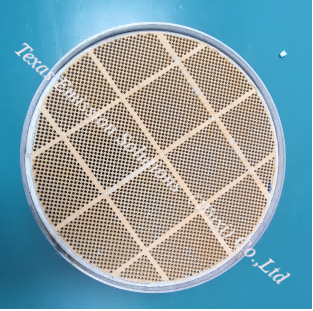

SCRF is an integration of the functions of SCR and DPF. The substrates of these two technologies, the catalyst coating and the wall-flow filter core, are combined into a single, integrated component. It looks like a traditional particulate filter (DPF), but its walls have porous structures to capture particles and are coated with Cu-SCR/Fe-SCR/V-SCR catalysts to remove NOx. SCRF is generally made of silicon carbide and cordierite, and some are made of aluminum titanate.

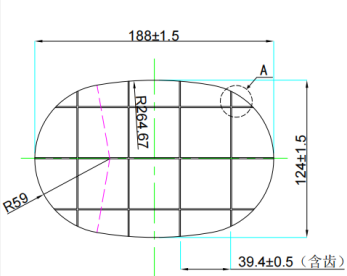

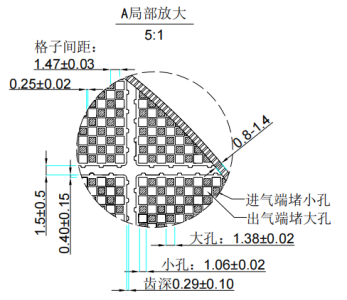

The above figure shows a single 3.12L of the irregular SiC substrate, with a 5:1 local magnification at point A. The large cells at the inlet are 1.38±0.02mm, and the small cells are 1.06±0.02mm.

In most cases, the substrate of this catalyst has an asymmetric DPF structure, that is, the pores at the inlet of the carrier are larger while the pores at the outlet are smaller. This unique structure can effectively reduce the back pressure of the filter and is also beneficial for the accumulation of ash inside the substrate.

TES SIC FE-SCRF TES SIC CU-SCRF TES COR CU-SCRF

2.How it works

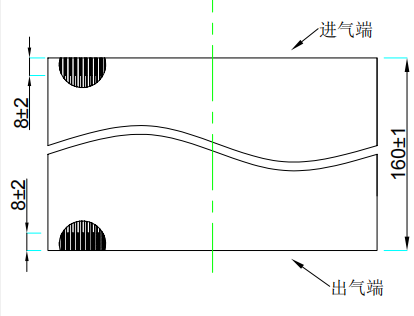

l Capture and Storage: The exhaust gas first passes through the porous walls of the filter, and particulate matter is physically captured and retained within the channels.

l Reduction and Conversion: Nitrogen oxides in the exhaust gas react chemically with urea that has passed through the filter walls under the action of the SCR catalyst coating, and are reduced to harmless N₂ and H₂O.

4NH3+4NO+O2→4N2+6H2O

2NH3+NO+NO2→2N2+3H2O

l Continuous Regeneration: Through engine management control, the exhaust temperature is periodically increased to oxidize and burn the captured particulate matter, cleaning the filter and maintaining its continuous effective operation.

3.TES SCRF Product Advantages and Applications

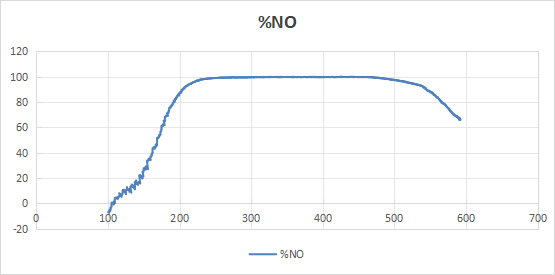

TES's SCRF has undergone rigorous testing and has shown excellent performance. We can provide the most optimized SCRF product design and catalyst formula according to the engine characteristics, platform layout, and specific regulatory requirements of our customers. The Cu-SCR conversion efficiency reduces NOx by more than 90%.

As of September 2025, TES has supplied more than 10,000 SCRF products in batches:

n Euro 6 passenger car aftermarket SCRF.

n China 6b light-duty diesel vehicle aftermarket

n Heavy-duty diesel vehicles (HDV) and non-road mobile machinery (NRMM)

TES CANNED SCRF

Catalyst sample test data

Test Specimen: A core section taken from the center of a full brick, cut to 18 mm × 18 mm × 75 mm.

Test Temperature: 100℃-600 °C.

Gas composition: Balance N₂, 500 ppm NH₃, 6 % O₂, 5 % CO₂, 5 % H₂O.